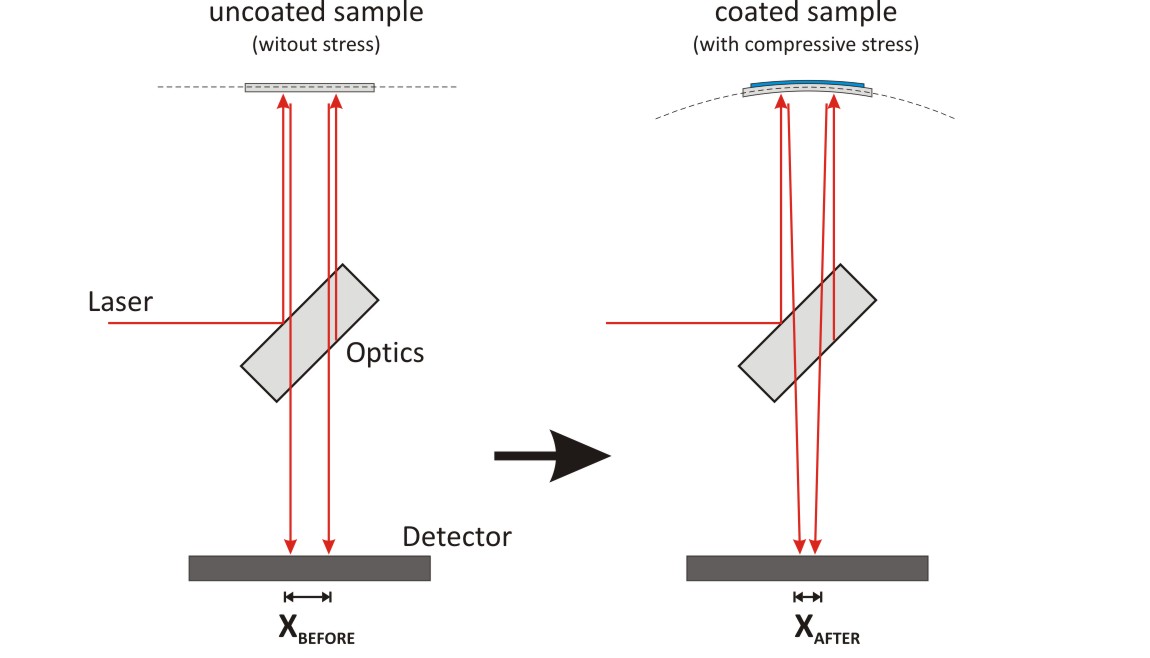

The principle of measuring the stress in thin films

The above illustrations demonstrate the principle of all our stress measurement systems:

The beam of a laser is split into two parallel ones.

These beams are directed onto the sample. As one side of the

sample is (at least 3%) reflecting the beams they are redirected

back onto a detector where the actual distance of the beams is measured.

Before the coating the measured distance Xbefore equals the inital

laser beams distance after the splitting optic. After the coating

process, when the sample is covered with a stressed film(system),

the stress can lead to a bending of the sample. This occurs all

the more, as the sample is thinner. The laser beams are not

reflected parallel anymore. The measured distance of the

beams on the detector, Xafter, can then be smaller or

greater than the initial value.

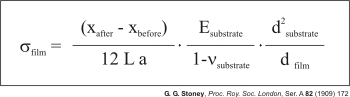

By the following Stoney-formula the stress in the thin film

can be calculated by using the change in the measured laser beams distances.

with:

| SIGMAfilm | Stress in the film |

| Esubstrate | Young's modulus of the substrate |

| vsubstrate | Poisson ratio of the substrate |

| dsubstrate | Thickness of the substrate |

| dfilm | Thickness of the film |

| L | Distance sample-detector |

| a | Distance of the laser beams on the sample |