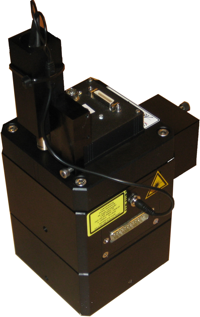

In-situ stress measurement system SIG-2000SP

Field of applikation

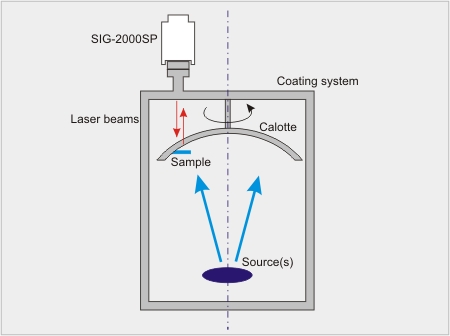

The stress measurement system SIG-2000SP is optimized

to measure the stress in-situ in thin films already during

their deposition onto a reference substrate. It is applicable

in nearly all kind of "box-coaters" where the system is

mounted outside the vacuum chamber leading the two laser

beams through a window.

On the substrate holder (i.e. the

calotte or the planetary system) a reference sample is

mounted inside a special sample holder. This allows to scan

the sample and determine the actual bending in every turn.

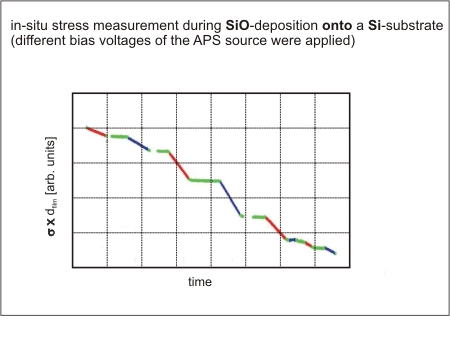

This system is very helpful in developing new film systems,

because a set of parameters, e.g. different bias voltages

can be applied during only one deposition run while the

experimenter studies the actual influence of the forming

stress.

The principle:

Technical data:

| Resolution limit: | Better than +-30MPa at a 150µm Si substrate with a 100nm film (at rpm of aprox. 60 per min.) |

| Substrates: | Nearly all materials, one side at least 3% reflectivity, typical thickness from 100µm to 1000µm |

| Sample holder: | Available for any substrate sizes smaller than 30mm x 30mm. |

| Detector: | CCD line detector, optional high-speed |

| Laser / Optic: | 650nm diode laser module. Other wavelengths available. Beam splitter produces two beams with a separation of 10mm. |

| Size: | 12cm x 12cm x 25cm |

| Weight: | 6kg |

| Software: | Special Software with data export to e.g. ".csv"-files. The complete history of measurements is saved in a clear structured database. |

| Mounting: | To connect the system to the coating system, flanges and adapters are provided by sigma-physik |

Example measurement: